Water is one of our most valuable resources. Life on this earth would not be possible without it. As a healthcare company, we too are dependent on water: We need drinking water of the highest quality to ensure safe patient care. It is crucial for hygiene and for their well-being. We also use water to manufacture our pharmaceutical products.

We want to cover our daily water requirements as efficiently as possible. The greatest potential for saving water lies in the processes for the manufacture of our products, for example cooling or sterilization.

Water is also an important component of some pharmaceutical products, such as infusion solutions. We cannot reduce this use.

An adequate supply of fresh water is important in hospital operations in order to meet the highest hygiene standards. We strive to use water as efficiently as possible in our clinics, but the potential for savings here is limited.

Vital and pure: Water in pharmaceutical products

The water used in our products must meet strict quality requirements so that we can guarantee quality and safety for patients. When used in infusion solutions, it must be of an even higher quality than drinking water.

Kirsten Nyland

Senior Vice President, Environmental & Occupational Management at Fresenius Kabi

“Reliable access to clean water is essential for our business. At the same time, we know that only 0.5 percent of the world’s water resources are drinking water. To conserve this scarce resource, we operate a comprehensive water management system.”

We distil water or filter it in a special process to remove germs and other impurities. We use this water for injection (WFI) as an ingredient in medicinal products.

A clear approach: Efficient water consumption in production

In order to use water in our processes in a conscious and efficient way, we have implemented water management systems at all our production sites.

Regular analysis shows us which production sites are at high risk of water shortages. Here in particular, we are working to identify potential savings.

To counteract water shortages, we set ourselves a specific target in 2024:

Details on our goals can be found under Our sustainability ambition.

You can gain an insight into how we use water in production and what aspects are relevant in our Highlight story: The journey of water in production.

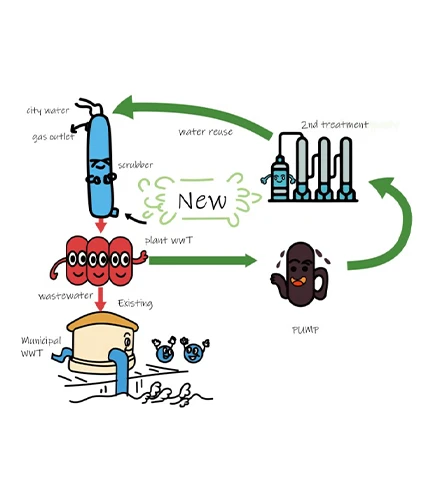

China: Wastewater reclamation for more sustainable water use

At our site in Beijing, China, we produce medicines for the treatment of chronic kidney disease. A new filter system enables us to reuse water that has previously absorbed an organic solvent, rather than sending it to the wastewater treatment plant. We thereby save 20,000 m3 of water per year, reduce the need for fresh tap water, and lower the costs of water procurement and treatment. This improves the availability of water for the local community.

Handling antibiotics in wastewater

Handling water in compliance with the law and in a controlled manner is a top priority for us – including when it is returned to the environment from our production processes. One important aspect is how we handle antibiotics: These medicines should help people and not cause harm. However, they can enter the environment via wastewater and enable the development of bacteria that are resistant to antibiotics. To solve this problem, we engage in responsible antibiotic production. We have also been a member of the Antimicrobial Resistance Industry Alliance (AMRIA) since 2020 and are working on solutions together with associations and other companies.

Test centers for drinking water: Clinics as guardians of water quality

To maintain the highest standards of hygiene in our healthcare facilities, we need sufficient fresh water. We monitor it in all our facilities to detect any contamination or deviations in its quality. In Germany, some of our clinics even serve as test centers for the municipal drinking water supply. We communicate directly with the authorities and inform them if we detect critical deviations from drinking water standards. In this way, we protect not only our patients, but also the population in the areas concerned.

Crisis management: Water treatment and emergency supplies

All hospitals have emergency plans in place to ensure patient care even in the event of supply bottlenecks. If fresh water should become polluted or contaminated with hazardous substances, our hospitals can use water treatment techniques.

In such cases, our German hospitals can for example deploy additional water treatment modules upstream of their own networks and thus use their own treatment systems. Most of our Spanish hospitals use a technology that leaves a reserve of water in the pipes, so that we can maintain a supply in the event of a drinking water outage.