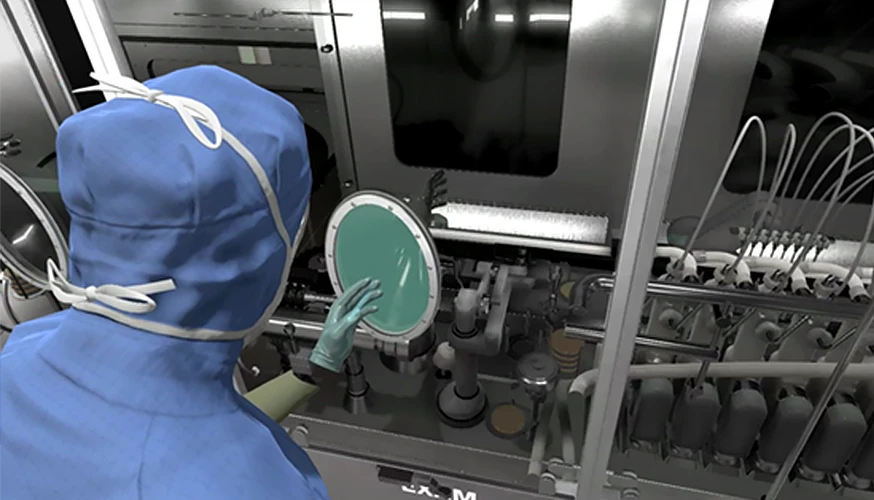

Virtual reality training at Fresenius Kabi

With the introduction of virtual reality (VR) training at Fresenius Kabi, new employees in cleanrooms – a controlled environment designed to minimize airborne particles, microbes, and other contaminants – are able to familiarize themselves with the cleanroom setting in a realistic way before physically entering one. These VR training courses are not just an innovation topic; they also build the confidence needed to protect product quality. Melrose Park, U.S. was the first site to implement the system formally in 2022 followed by Grand Island, U.S. In February 2025, the VR Cleanroom Simulator was also implemented at our site in Graz, Austria.

Bringing the cleanroom to life: Initial experiences with VR training

The VR simulation accurately replicates the cleanroom environment, including machines and equipment, allowing employees to understand important aseptic manufacturing principles in real time. The result is a smoother transition to hands-on work.

“New employees have expressed positive feedback about the VR training experience. The simulation provides them with valuable exposure to the cleanroom environment and equipment. They feel more confident entering the cleanroom after completing VR training.”

A comprehensive training tool

VR serves as an interactive training tool that provides real-time feedback. The system immediately identifies mistakes and provides guidance on how to correct them. To ensure that VR training aligns with real-world cleanroom conditions, the modules reflect authentic manufacturing conditions and procedures used at our Fresenius Kabi facilities.

The VR training program offers, e.g., modules for proper wiping techniques, hand sanitization protocols, microbiology monitoring, and first-air concept. The latter refers to the supply of filtered air that should not be interrupted prior to contacting exposed products. If interrupted, the air could become contaminated again.

One of the most significant advantages of VR training is its impact on learning speed and retention. Compared to traditional training methods, the onboarding period has shortened, allowing new hires to become productive members of the team faster than before. This efficiency translates to reduced errors and a higher overall competency level among new employees.

A rising potential for cleanroom training

As VR technology continues to evolve, so does its potential for cleanroom training. The integration of VR training at Fresenius Kabi represents a significant leap forward in cleanroom workforce preparation. The role of VR in training is expected to expand further, making cleanroom education more effective and accessible than ever before.

“I see this technology only getting better and more customized which would really help for more in depth training of the operators; and of course it’s fun to do in my opinion.”